"Intelligence-Awareness" information system for operating & manufacturing progress has been established on the basis of Internet, mega data and cloud computing, which realizes the visualization, digitalization, real-time, mobility for these processes According to the comprehensive and meticulous analysis of personnel, machine, raw material, method, and environment, Mega data can be collected, analysed and output timely & accurately. Realizing the objective of managing (informatization) & controlling (automation) in intelligent methods.

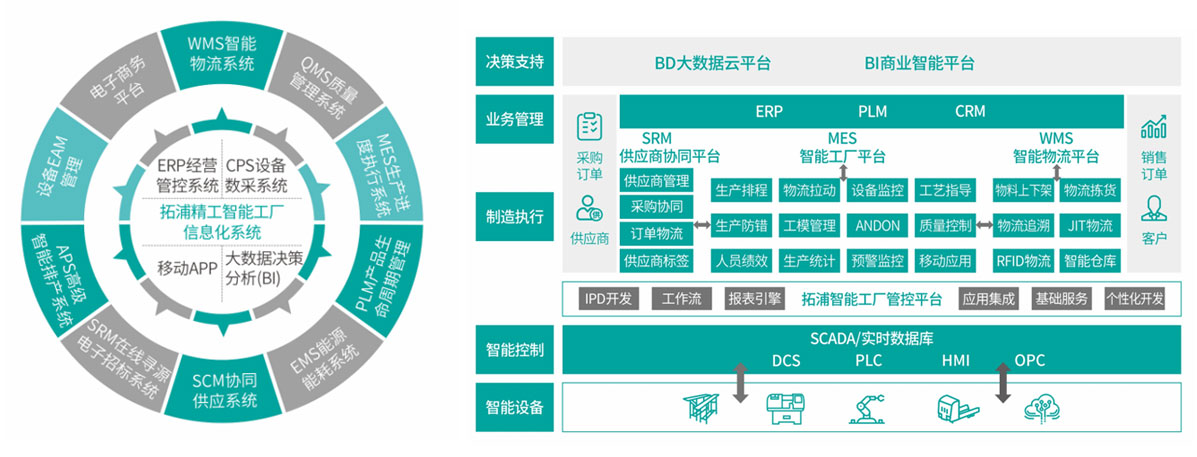

The company's information system includes 14 modules: ERP, PLM, MES, CPS, APS, SCM, QMS, WMS, Bl •••etc. Based on this industryleading informative control system, Mega data for production & operation can be collected, transferred, analysed automatically at every second. Customer even can remotely monitor the real-time status for production line to get the needed real-time information.